- Reminders

- Whisky

- Blog

How Whisky is Made: A Journey Through Ingredients and Craftsmanship

Whisky is more than just a spirit—it’s a crafted experience that reflects centuries of tradition and skill. Behind every bottle lies a fascinating and meticulous process where simple ingredients such as grain, water, and yeast are transformed into something extraordinary. From the careful selection of grains to the magic that happens in oak casks, whisky-making is a journey that blends art and science in perfect harmony.

In this article, we'll explore the steps that turn raw ingredients into the rich, flavourful whisky that we know and love.

Key Ingredients: The Building Blocks of Whisky

Grain: The Foundation of Flavour

The primary ingredient in whisky is grain, and the type of grain used plays a crucial role in defining the flavour profile of the final product. Different types of whisky use different grains:

- Barley: Barley is the star ingredient in Scotch whisky, especially Single Malt Scotch. It imparts a rich, malty flavour and, in some cases, a smoky character when peat is used during the malting process.

- Corn: Corn is the dominant grain in Bourbon, a quintessentially American whisky. By law, Bourbon must consist of at least 51% corn, which contributes to its distinctive sweetness and full-bodied flavour.

- Rye: Rye gives Rye whisky its signature spicy kick. In American Rye whisky, the mash bill must contain at least 51% rye, resulting in a bold, peppery taste that sets it apart from other types of whisky.

- Wheat: Wheat is sometimes used in combination with other grains to add a softer, smoother profile to whisky. Wheated Bourbons, for example, are known for their mild and sweet characteristics.

Water: The Lifeblood of Whisky

Water is essential at every stage of whisky production, from mashing to fermentation and dilution before bottling. Hence, the quality and source of the water is important during the production process as it can significantly influence the final characteristics of the whisky. Many distilleries are strategically located near natural springs or rivers, ensuring a pure and consistent water supply.

Yeast: The Catalyst of Transformation

Yeast is the microorganism responsible for converting the sugars into alcohol from the grains when through fermentation. Different strains of yeast can impart unique flavours and aromas to the whisky, adding complexity and depth. The choice of yeast, along with the fermentation conditions, plays a critical role in shaping the character of the spirit, making it a key component in the whisky-making process.

The Whisky-Making Process: From Grain to Glass

1. Malting: The Beginning of the Journey

The journey of whisky production begins with malting, a process primarily associated with malt whisky. To be categorised as malt whisky, the production process the liquid involves a fermented mash based on malted barley. For Single Malt Scotch, which is malt whisky produced by a single distillery, barley grains are soaked in water to initiate germination, which activates enzymes that convert the starches in the barley into fermentable sugars. Once germination is underway, the barley is dried in a kiln, halting the process. In some Scotch whiskies, peat—a type of soil rich in organic matter—is used as fuel in the kiln, which creates a distinctive smoky flavour to the malted barley.

2. Mashing: Extracting the Sugars

After malting, the dried malted barley, now known as "grist," is ground into a coarse flour and mixed with hot water in a large vessel called a mash tun. This process extracts the fermentable sugars from the grain. The resulting mixture, known as "mash," is stirred to dissolve the sugars into the water, creating a sugary liquid called "wort." The quality of the wort is crucial, as it forms the foundation for the different flavours that develop during fermentation.

3. Fermentation: Turning Sugar into Spirit

The wort is then transferred to fermentation vessels, which are traditionally made out of wood or stainless steel. Yeast is added to the wort, initiating the fermentation process. As the yeast consumes the sugars in the wort, it produces alcohol and carbon dioxide. This process typically lasts several days, resulting in a liquid known as "wash" with an alcohol content of around 6-8%.

4. Distillation: Refining the Spirit

The wash is then distilled, which is a process that separates the alcohol from water and other components. This concentrates the alcohol and refines the flavours in the whisky. In Scotch whisky production, distillation typically occurs twice in copper pot stills, while Irish whisky may be distilled up to three times for a smoother finish. The first distillation produces a liquid known as "low wines", which is then distilled again to create "new make spirit", also known as "white dog" in Bourbon production.

During distillation, the spirit is divided into three main parts: the head, the heart, and the tail. The heart, which contains the purest alcohol and the best flavors, is carefully collected, while the heads and tails—containing undesirable compounds—are either discarded or re-distilled. This selective process is important in determining the quality and character of the final whisky.

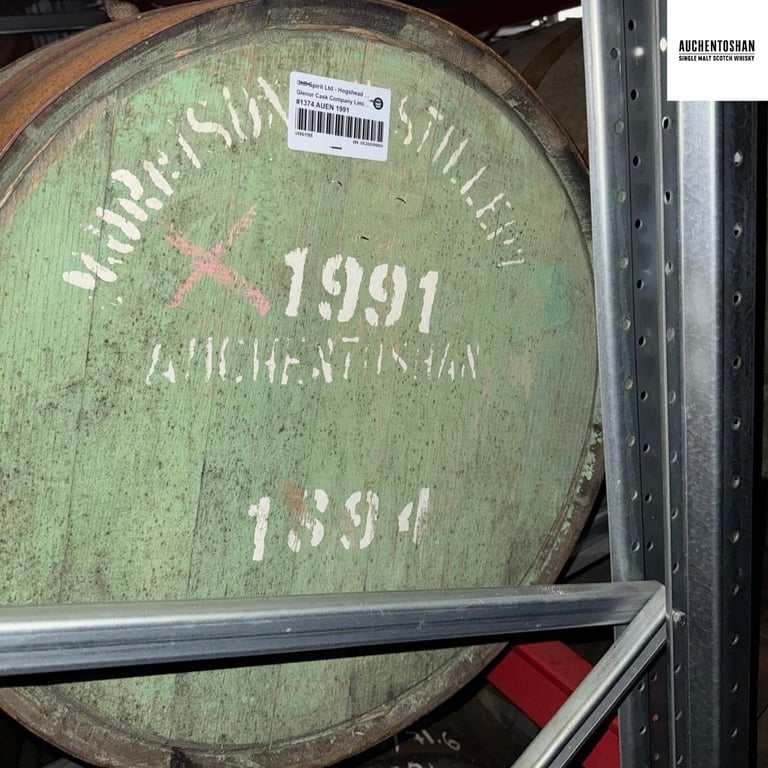

Maturation: The Art of Aging

The new make spirit is transferred to oak casks for maturation, a process that can last anywhere from a few years to several decades. The type of cask, the previous contents (such as sherry, bourbon, or wine), and the length of aging all significantly influence the whisky's final flavour. During maturation, the whisky interacts with the wood, absorbing compounds that add complexity, depth, and richness to the spirit. The aging process also allows for the gradual evaporation of alcohol and water, known as the "angel's share", which further concentrates the flavours.

The minimum aging period varies by region, with Scotch whisky requiring at least three years of maturation. However, many premium whiskies are aged much longer, developing a more sophisticated and nuanced profile over time and also contributes to the value of the whisky.

Bottling: The Final Step

After aging, the whisky is typically diluted to bottling strength with water, usually around 40% ABV (alcohol by volume), although some whiskies are bottled at cask strength, retaining their full potency. Before bottling, the whisky may be filtered to remove any impurities, ensuring a clear and stable product. Once bottled, the whisky is ready to be enjoyed, whether by collectors, connoisseurs, or casual drinkers.

Conclusion: The Craftsmanship Behind Every Sip

The production of whisky is a fascinating blend of tradition, precision, and a deep respect for natural ingredients. Each step in the process—from the selection of grains to the quality of water, the intricacies of fermentation, distillation, and maturation—contributes to the unique identity of the final product. Understanding how whisky is made not only enhances the appreciation of the spirit but also highlights the dedication and skill of the distillers who craft it.

Whether you’re savoring a peaty Scotch, a sweet Bourbon, or a spicy Rye, knowing the craftsmanship behind every sip enriches the experience. So, the next time you pour a glass of your favorite whisky, take a moment to appreciate the journey it has taken from grain to glass—a journey shaped by tradition, innovation, and a passion for perfection.

More Content

View More